Challenges of managing Grade crossing safety after PTC

To provide more consistent, predictable and reliable service for rail customers, North American Railroad operators are moving toward a Precision Scheduled Railroading (PSR) service model. The push to improve the efficiency and safety of the entire railroad operation has never been greater. Grade crossing safety remains one of the most critical concerns in the railroad industry, and safety must always remain the top priority.

In the past, the traditional train operating model focused on moving long trains to maximize capacity and yield the greatest efficiency. A train could be canceled if it didn’t meet a specific length requirement. With the goal to optimize scheduling and cost-efficiency, PSR now involves running shorter trains. However, the variable train length can create operational gaps, causing inefficiencies and safety concerns at grade crossings. This problem is further amplified when passenger rail operators are increasingly sharing tracks with freight rail, and the train weight and length between the two operators are vastly different. As a result, crossing activation systems, typically set up to detect trains based on a fixed location, may become less efficient or lead to delays if the train is shorter than expected (because it doesn't trigger the detection systems in the same way as a longer train). This also creates safety issues, where trains might not trigger the gates or sensors in time.

Fortunately, a solution is emerging. The industry is improving grade crossing safety with the integration of PTC (Positive Train Control) systems, specifically with the new PTC Activated Crossings function. This new standard enables communication between the Onboard Computer (OBC) and the Crossing Wayside Interface Unit (xWIU), allowing more accurate and timely crossing gate operations.

However, road vehicles and pedestrians stuck in grade crossings remain invisible to standard PTC. As crossing accidents often result from poor visibility, lack of warning signals, and misjudgments by road users, the gaps in safety need to be addressed immediately. While the successful rollout of PTC systems has improved train safety, the industry must now turn its attention to implementing PTC 2.0 technology solutions. This next phase, envisioned by the FRA, will further protect grade crossings and maintenance-of-way operations.

The solution: reliable object detection and classification with timely alerts

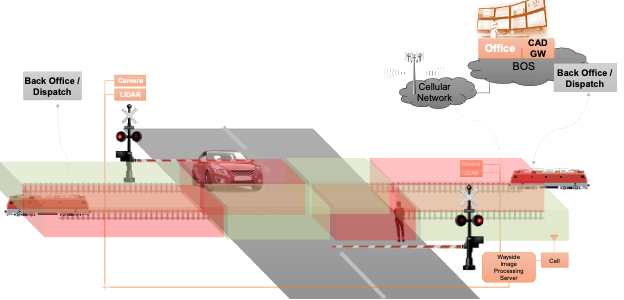

LILEE SafeRail™ provides a critical solution to improve safety and efficiency at grade crossings. The multi-sensor, AI-powered crossing collision avoidance system offers reliable object detection and classification, alerting approaching rail vehicles (MOW vehicles or locomotives) and the back office in real-time to potential hazards.

Key benefits of SafeRail™ include:

- SafeRail is an AAR S-9202 compliant system with embedded Wayside Message Server (WMS) capabilities and highly reliable and redundant 5G communications.

- SafeRail improves safety, reliability, and cost-efficiency with real-time knowledge and visibility of crossing health status from the back-office management console.

- SafeRail’s innovative sensor fusion technology that combines multiple sensors divides the crossing into monitored sections. It enables rail operators to reliably detect road vehicles or pedestrians entering a grade crossing and immediately informs the rail vehicle operators and the back office to take corrective action.

Crossing Collision Avoidance

SafeRail™ can be used independently or integrated with other safety or PTC solutions. It is also especially effective for maintenance-of-way (MOW) operations, providing a comprehensive Limits Compliance and Collision Avoidance System (LCCAS) to reduce the risk of human injury, equipment damage, and operational disruptions.

For more information on how to enhance your grade crossing safety and efficienty, contact us today to learn more.